By: Meggan Shoberg

The health and safety of students in the classroom is of crucial importance. According to the U.S. Department of Education, currently 55 million people spend their time in K-12 buildings. That is about 20 percent of our current population! Teachers, students, administration, and staff are all spending a majority of their time indoors, between the walls of these vital buildings. The students who reside in these buildings consume more oxygen than their adult counterparts, and are afflicted by poor indoor air quality, inefficient energy systems and health risks at a higher rate.

Many Midwest schools have been recipients of Energy Star Awards, and that is an amazing first step to creating the best environment for learning. There are a couple of key considerations to make when analyzing your school building’s efficient and indoor air quality:

- Energy Star and other energy benchmarking programs are a standard for adults, not children. So, area schools should be looking to not just achieve minimum standards, but exceed them to accommodate their most vulnerable residents.

- Look at the building’s efficiency during occupied periods of time. While over a 24-hour period, a school may warrant acceptable results, these facilities are unoccupied a portion of the time and experience high traffic during school hours. Energy efficiency measures should account for the time that the building is actually using energy, not when it’s sitting dormant.

Over the next few months, we will be diving into the topic of efficiency, maintenance and indoor air quality of schools. We’ll be covering the benefits, low-cost improvement measures, EPA tools, and how Metropolitan Energy Center is a great partner for your school’s efficiency project. Stay tuned in the coming months as we explore this critical compenent to protecting the health of our students, and contact Meggan@mec.bluesym10.work with questions about how your school can improve its efficiency.

By: Mary English

Those that have been in the lighting business a long time can probably remember the struggle of energy efficient lighting: The product came into the market higher priced than their older cousins, the fluorescent light bulb. They were too bright. Too white. What was the benefit?

The benefit, it turned out, was energy savings. Lots and lots of energy savings. (Some would say the aesthetics have since caught up to this benefit as well.) However, since the habit was to change out light bulbs once the old ones aged and burned out, the lighting retrofit took a while to gain traction.

We now find ourselves in the same situation with a new product package in the commercial market: the humble motor, fan, and VFD packaged retrofit for HVAC and refrigeration.

HVAC takes up to 30-50% of your utility bills according to the US Department of Energy and field experts — and the vast majority of commercial properties are wasting money on inefficient equipment. This is due to manufacturers cutting costs with the original cheaper components to boost margin. One of these main components is the motor that drives the air flow in forced air systems.

There has been a new kid in town for quite some time, but it remains virtually unknown to those in the energy efficiency business: electronically commutated motors (ECM). These motors are 70% more efficient than their older cousins, the shaded pole motor. This technology has been around for decades, but has remained virtually unused since it hasn’t been mandated by code.

The mandate for brand new equipment is about to change from the DOE this June for brand new installs, but this still leaves almost 90% – including relatively new systems – in HVAC and refrigeration installed with these old motors that burn through your utility dollars much like the old incandescent light bulbs. Most people upgrade their equipment when it breaks down, just like businesses waited until their light bulbs burned out in the old days. This thinking is short sighted, especially when you see how much impact on energy use a new motor retrofit can have on your bottom line.

A Kansas City based company – FridgeWize – is out to change minds and bring awareness to this opportunity in the commercial market. They are uniquely positioned in that they are the only company in the U.S. with a business model to retrofit high efficiency ECM’s to end-user businesses and property owners nationwide.

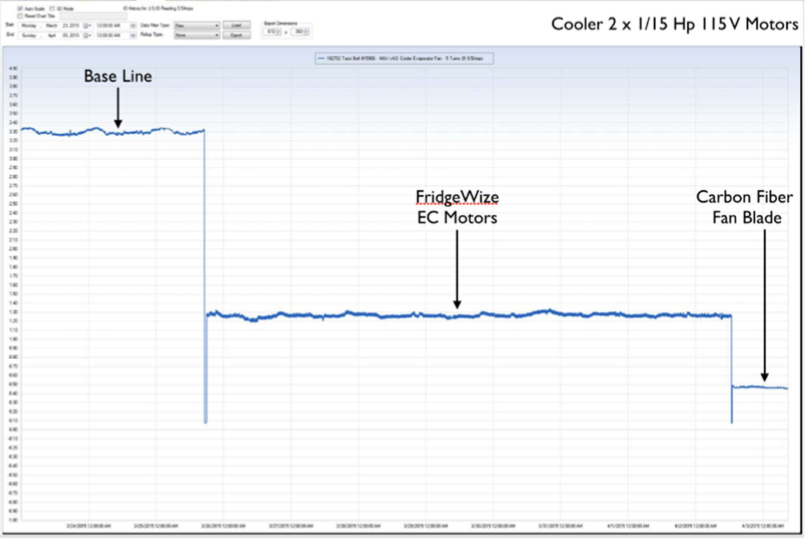

Founded in 2010, they have already done retrofits nationwide in major chain restaurants. One such nationwide retrofit saved over 5-million kilowatt hours (kWh) over 450 restaurant locations – that is the equivalent of a 2 megawatt solar field (at almost five times less the cost of renewable installs). For energy wonks, the numbers are fun to see. In refrigeration, FridgeWize consistently sees 80-90% energy savings when retrofitting an old shaded pole motor with an ECM and their own carbon fiber blade where they have a patent pending (see Image 1) on the walk-in cooling units.

Image 1. Testing measurement of energy pull via amps from old motor (Base Line) to new ECM and carbon fiber blade for walk-in storage refrigeration.

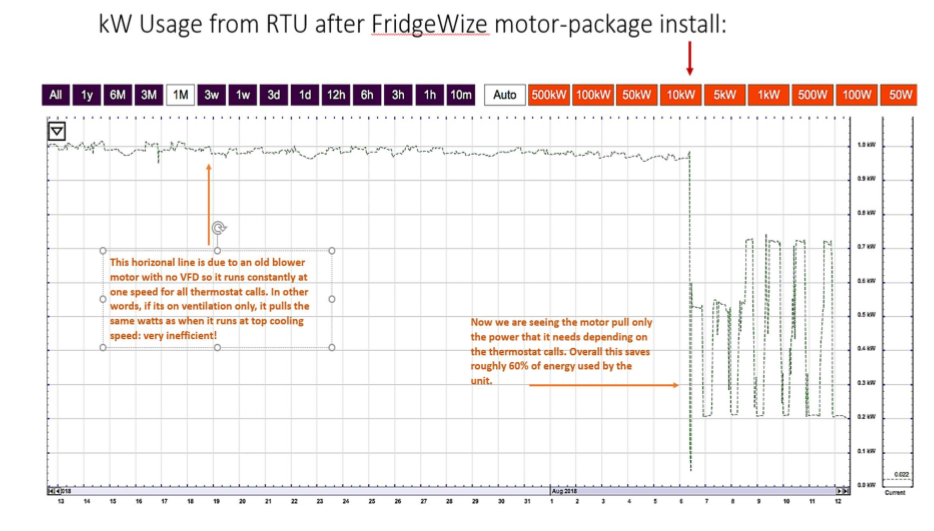

In more traditional HVAC air delivery – such as roof top units, air handlers and VAV fan boxes – the kWh savings are not as aggressive, but still better than any other more common retrofits in the industry; and roughly 10% the cost of replacing an entire HVAC system. FridgeWize in several case studies has seen roughly 60% reduction in kWh’s on the power needed to operate the blower fans when using ECM’s along with a variable speed drive (VFD). This is illustrated in Image 2.

Image 2. Before and After an ECM plus VFD and smart card install on a roof top unit at a large manufacturing facility in the Kansas City area.

FridgeWize has seen validation in the last several years through international awards won in the industry. In 2016 they won the illustrious Energy Efficient Product of the Year for HVAC&R. The firm’s CEO, Ryan Grobler, was presented the award in London after beating out high profile products from the likes of Mitsubishi and Samsung manufacturers.

“We are excited to be in Kansas City as this community thrives in sustainable leadership. We have been flying below the radar, but with the aggressive rebates being offered by KCP&L for our products, we don’t think we will be a secret much longer,” said Grobler. “With the rebates, we’re looking at return on investment for these retrofits in 1 – 2 years max.”

The rebates Grobler mentioned are the 75% HVAC bonus rebate being offered by KCP&L through September of this year, or when the money runs out – whichever comes first.

For more information on FridgeWize and their retrofit products, they can be reached at 913-579-8484 or info@fridgewize.com.

Wed, May 23 | 2:30 pm | Project Living Proof | 917 Emmanuel Cleaver II Blvd, KCMO

Kansas City Regional Clean Cities is hosting a grant workshop on three new funding opportunities totaling more than $140 million nationwide. These programs cover diesel emissions reduction, low- and zero-emission transit fleets, and infrastructure and super-fast charging, plus other projects. We’ll cover eligibility, the application process, financial and cost-share requirements, and much more in this free workshop.

All interested potential grant applicants are cordially invited to participate. This includes state and local governments, transit agencies, MPOs, non-profit organizations and school districts. Although for-profit companies are not eligible to apply directly for these grants, Clean Cities routinely works with our corporate fleet members to administer grants for their projects. Interested businesses are welcome to attend.

Join us in person at Project Living Proof, or attend virtually via GoToMeeting or telephone at (646)749-3122, Access Code: 448-679-701. If attending in person, please park at the Anita Gorman Discovery Center, 4750 Troost Avenue, Kansas City, MO, then follow the boardwalk north to PLP’s back door.

For questions or to RSVP for the workshop, email David Albrecht or call (816) 531-7283.

By Tami Alexander, Central Kansas Clean Cities Coordinator

According to the U.S. Energy Information Administration’s January 2018 Monthly Energy Review, CO2 emissions for the transportation sector have now surpassed emissions for electricity generation. Greenhouse gas emissions from transportation make up 27% of all emissions (EPA, 2018). So, what can we as consumers do to help? There are the obvious solutions such as driving less, carpooling, and using public transportation. But what about those times when a personal vehicle is needed? The answer: Biofuels!

So, what are biofuels? You have likely heard them referred to as ethanol or biodiesel. Ethanol is a plant-based replacement for petroleum gasoline and biodiesel is a mostly plant-based alternative for petroleum diesel. These fuels can be used in traditional internal combustion engine vehicles in place of their petroleum counterparts with little to no alterations needed.

Contrary to the popular belief that petroleum is made from ancient dinosaurs, it is actually the product of ancient plant material which decayed over millions of years in an oxygen-free environment, forming the fossil fuels of coal, oil and natural gas. Biofuels are also made from plant material which is processed into the fuels quickly instead of taking millions of years. The difference is biofuels are renewable, non-toxic, and emit much less CO2 and other pollutants than petroleum fuels.

So, what goes into biofuels? Biofuels can be made from many different products called feedstocks. Ethanol is grain alcohol and can be made from multiple sources including corn, sorghum, sugar cane and even grasses. Biodiesel can be made from vegetable oil, used cooking oil, and poultry or beef fat. Feedstocks can vary the amount of emissions produced by the fuels, but all are cleaner than petroleum fuels and renewable. And, they can produce the same quality of fuel.

Many studies have touted the importance of biofuels in the move to lowering emissions and becoming carbon neutral (IRENA, 2018). One major advantage is that biofuels use the same infrastructure as petroleum fuels and can be fairly easily used in most vehicles with little to no modification necessary. In fact, 97% of gasoline in the US contains 10% ethanol and can be used in any gasoline engine. The ethanol boosts the octane of petroleum gasoline which is necessary in today’s higher performing engines. All gasoline vehicles model year 2001 or newer can burn E15 (a blend of 15% ethanol gasoline and 85% petroleum gasoline). Flex-fuel vehicles can use blends up to E85 (85% ethanol). And most manufacturers of diesel vehicles warranty their engines to use blends up to B20 (20% biodiesel and 80% petroleum diesel).

Biofuels are more difficult to find than petroleum gasoline, but their availability is increasing. Check out the Alternative Fuels Data Center on the Department of Energy’s website to find out where you can buy biofuels in your area. (www.afdc.energy.gov/stations) The website can also help you find vehicles that use biofuels and give you other important information about biofuels and other alternative fuels.

References

International Renewable Energy Agency (IRENA). (2018, February). Renewable energy prospects for the European Union. Retrieved from: https://irena.org/-/media/Files/IRENA/Agency/Publication/2018/Feb/IRENA_REmap-EU_2018_ summary.pdf?la=en&hash=818E3BDBFC16B90E1D0317C5AA5B07C8ED27F9EF

U.S. Energy Information Administration. (2018, January). Monthly energy review. Washington, DC: U.S. Department of Energy Office of Energy Statistics.

U.S. Environmental Protection Agency (EPA). (2018, February 6). Inventory of U.S. greenhouse gas emissions and sinks: 1990–2016. Washington, DC: U.S. Environmental Protection Agency.

Time/Date:

Thursday, November 16, 2017 from 10:30 AM to 1:00 PM (CST)

Location:

MARC Boardroom | 600 Broadway Blvd #200 | Kansas City, MO 64105

Description:

Energy Efficiency and Property Assessed Clean Energy (PACE) provide increased support for strong local economic development. This event will provide economic developers and municipal leaders information on Kansas City Power & Light’s energy efficiency offerings, specifically who can take advantage of them and what the expected local impact of these offerings can mean for your community. Additionally, hear about PACE’s impacts on your community and how you can use it to increase economic development locally. Join us for this free event!

Speakers:

PACE for commercial properties

- Show Me PACE – Commercial PACE (Josh Campbell)

- Missouri Clean Energy District – Residential PACE (John Harris)

Energy Efficiency for commercial properties

- Kansas City Power and Light (Kevin Brannan)

PACE Case Studies

- Municipal Speakers (Dennis Murphey, City of Kansas City; and City of Independence invited)

- Residential PACE (John Maslowski, Renovate America)

- Commercial PACE (Rob Shear, PACE Sage, and property owner)

About Us

Metropolitan Energy Center (MEC) is a 501(c)(3) nonprofit organization. Our mission is to create resource efficiency, environmental health, and economic vitality in the Kansas City region – and beyond. Learn more about us and our programs.

Recent Posts

- Spring Cracks Open at Project Living Proof

- Future Work Is Here: Can We Take the Offer?

- Kansas City’s Agora: Safeguarding our Library as a Sanctuary and Beacon of Innovation

- Kansas City’s Future Depends on Smart Energy and Transportation Investments

- Driving Rural Innovation: Orange EV’s Push for USDA Support